3B-the fibreglass company is a leading developer and supplier of glass fibre products and technologies for the reinforcement of thermoplastic and thermoset polymers.

It has three state-of-the-art manufacturing facilities located in Belgium, Norway and India. Their products are designed and optimized to serve the automotive and wind industries and be incorporated into performance composites.

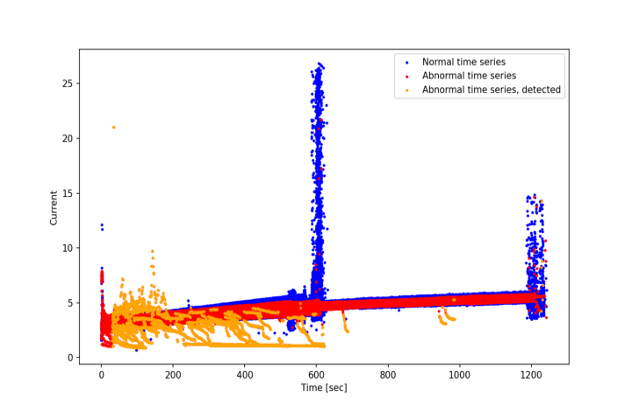

3B-the fibreglass company produces different types of fibreglass. The products are wound onto bobbins at typically 50km/h. The production is, to a high degree, automatic. One of the remaining manual procedures is detecting breaking fibres during the winding process.

Machine Learning for early break detection

3B-the fibreglass company collaborated with the National Competence Centre for HPC in Norway to investigate advanced machine learning possibilities for early break detection. In the 12 months of collaboration, an anomaly detection algorithm has been developed to detect breaks with a precision of 98.5%, a significant improvement from the current detection algorithm.

The results of this collaboration are beneficial for 3B in terms of supporting management decisions on developing their break-detection strategy. Further, the company is better prepared to assess the cost-benefit relationship of further educating its staff in data analytics, machine learning and modelling.